Thermography Systeme for Monitoring of Industrial Plants

IRMonitor is a flexible solution concept for early fire detection and temperature monitoring of industrial plants by means of thermography. Infrared cameras detect objects through their thermal radiation and are able to perceive certain characteristics regarding the condition of these objects, which conventional cameras cannot pick up. IRMonitor is thereby able to detect potentially hazardous situations based on critical temperature developments and to initiate security measures.

With its combinable hardware and software modules, IRMonitor offers a flexible solution for early fire detection and plant monitoring. An IRMonitor system can be set up with a large number of infrared cameras so that even large areas with many different angles can be fully monitored. This allows reliable system solutions for both simple and complex applications that can easily be adapted to suit the customer’s specific requirements.

Configuration

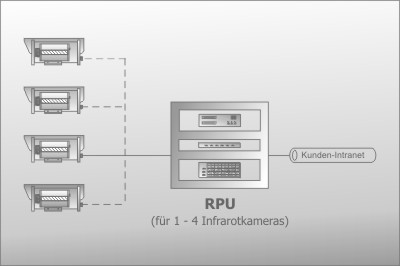

Configuration model 1: IRMonitor-RPU (Remote Process Unit)

An IRMonitor-RPU system comes with a robust control cabinet that includes an embedded PC with additional peripherals for self-contained control of monitoring cycles with up to 4 infrared cameras. Customers have the option of monitoring the userinterface via a remote operator console.

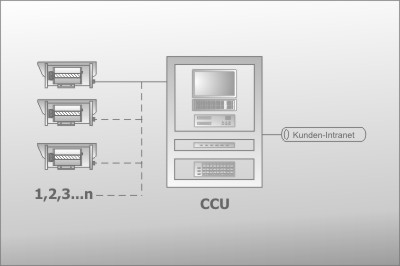

Configuration model 2: IRMonitor-CCU (Central Computing Unit)

This system concept is based on a powerful processing unit that enables the use of a multitude of sensor units (IR and

vision cameras). With the aid of CTUs (Camera Terminal Units), the cameras and their peripherals (e.g. pan/tilt heads) can be integrated into system solutions, even across considerable distances. Furthermore, the CCU concept offers a central interface and user console for the parameterization and visualization of the monitoring system..

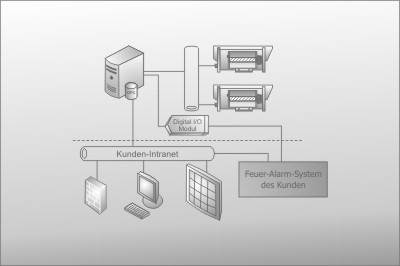

Configuration model 3: IRMonitor-CS (Client-Server)

IRMonitorCS manages a network of smart cameras, which independently monitor the area assigned to them. The alerting and control are either performed directly by the relevant camera interface or by a central camera manager. This concept is particularly suitable for applications that need a large number of cameras.

Features

- Wide-Area Monitoring with Infrared Cameras

Precise and Comprehensive Temperature Detection in Hazardous Areas - 24/7

Thermographic Monitoring around the Clock - Automated Procedure

Software evaluates thermal images and generates alarm signals - Cyclical Temperature Evaluation

Scanning and Comparison with Preset Thresholds in Defined Zones (Evaluation Areas) - Continious Output and Saving of Measuring Results/Image Data

Display and Archiving of Reference Data, Pre- Alarm and Alarm Events

- Trending Visualization with Temperature-Time Diagram

- Tamplate matching For monitoring of moving objects

- Live Image Automatic display of the live view if alarm occurs

- Spatial Visualization Diplay of all Zones in a Map View

- Rafineries

- Chemical Plants

- Gas and Oil Production

- Steelworks:

Mr. Cristian Ferber

Sales Manager Monitoring

Phone: +49 (0)4531/88011-18

Email: cristian.ferber@automationtechnology.de